The True Cost of Unreliable Freight in the Aftermarket Auto Parts Industry

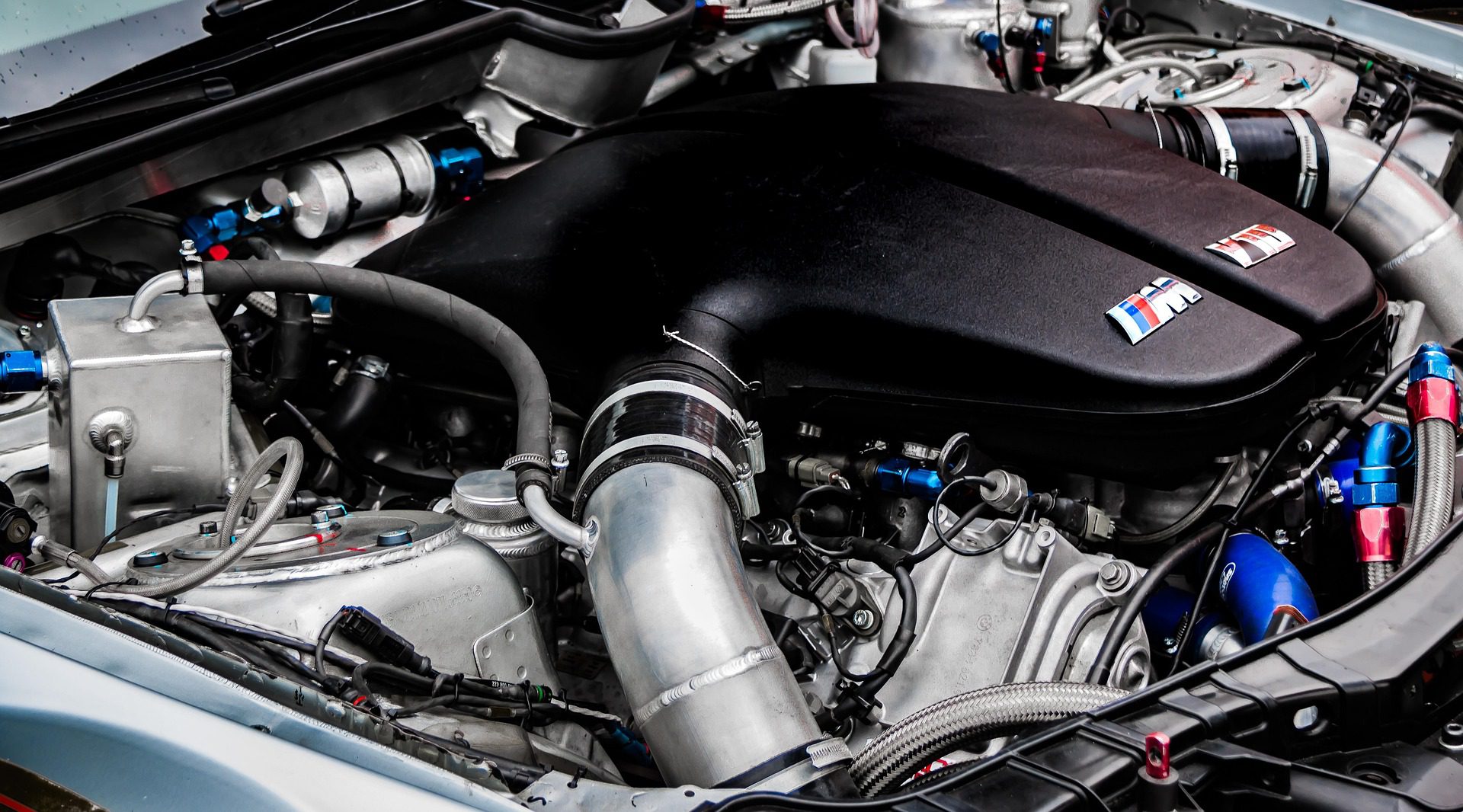

Unreliable freight in the automotive aftermarket isn’t just a logistics inconvenience – it’s a hidden drain on revenue, customer loyalty, and operational efficiency. Late shipments, customs hang-ups, and transit damage all exact a financial toll. This post explores data-backed evidence of those costs and examines current supply chain challenges (from port congestion to labor shortages and trade tensions) affecting auto parts logistics. We’ll also highlight how strategic freight management can mitigate these risks, with visuals and testimonial insights to illustrate the risks vs. rewards of a reliable logistics strategy.

Impact of Delays, Customs Issues & Damage on Aftermarket Supply Chains

Even minor freight disruptions in the auto parts sector can cascade into big problems. Consider what happens when a critical replacement part shipment is late, held in customs, or arrives damaged:

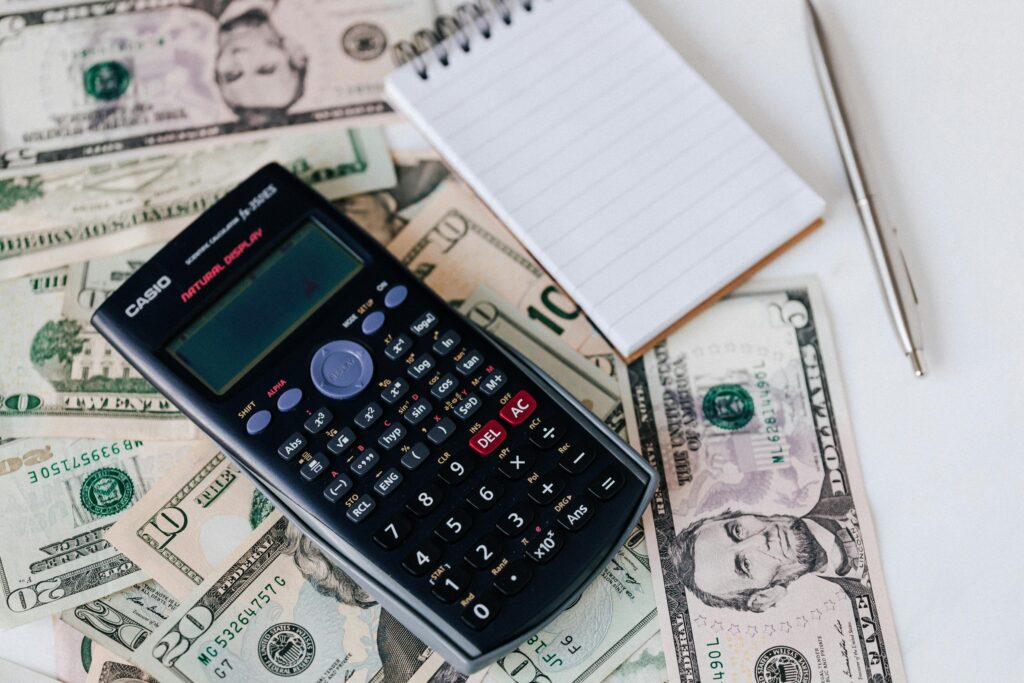

- Lost Sales & Revenue: When parts don’t arrive on time, stockouts halt repair jobs and frustrate customers. Nearly 60% of small and mid-sized businesses reported losing up to 15% or more of annual revenue due to supply chain delays. In other words, a single year of delays cost a majority of businesses a significant chunk of their sales. For auto parts suppliers, a delayed container stuck at port might mean idle service bays and lost orders as customers turn to competitors. Moreover, research shows even a one-week delivery delay can erode a product’s retail value by ~25% – per Maersk estimates – as items miss their market window. This lost value comes straight off the bottom line in markdowns or unsold inventory.

- Emergency Expedites & Reorder Costs: To recover from late shipments, companies often resort to costly workarounds – express air freight for backorders, rushed local sourcing, or after-hours labor – all of which inflate costs. One study found each delayed or damaged LTL freight shipment cost shippers nearly $2,000 on average when you factor in expediting and claims. On a larger scale, penalty fees for missed delivery targets (On-Time/In-Full, or OTIF) can pile up fast – averaging over $250,000 in extra costs for shippers in 2022. For an aftermarket auto parts distributor, that might include urgent re-shipments to dealers or hefty charges from customers who couldn’t service vehicles on time. These “firefighting” expenses directly eat into profit margins.

- Customer Churn & Brand Damage: Late or unreliable deliveries don’t just cost you once – they can drive customers away for good. In today’s on-demand world, repair shops and consumers have little patience for delays. Surveys indicate about 23% of shoppers won’t buy from a retailer again after a delayed delivery and 21% lose trust in the brand. Auto parts buyers (whether a DIY customer or a commercial garage) similarly remember who let them down. A body shop waiting on a delayed fender or sensor might switch suppliers to avoid future downtime. Over time, inconsistent freight service tarnishes your reputation, leading to churn and lost lifetime customer value far beyond the immediate sale.

- Hidden Inventory Costs: Unreliable transit times force companies to pad their inventory as a buffer. If you can’t trust shipments to arrive as scheduled, you hold more safety stock – tying up capital in warehouses. One logistics report notes that freight delays and poor reliability drive up shippers’ carrying costs and even “penalties” in the form of buffer stock. In the aftermarket parts world, that might mean excess brake pads or filters sitting on shelves “just in case,” which increases storage expenses and risk of obsolescence.

- Product Damage & Returns: Rough handling and transit delays also increase the risk of damage to auto parts – from cracked windshields to dented body panels. Damaged goods trigger return logistics, replacement orders, and scrapped inventory. Industry data shows up to 11% of unit loads arrive at distribution centers with some degree of damage. In monetary terms, in-transit damage costs U.S. businesses about 0.5% of gross sales – roughly $1 billion annually. For aftermarket suppliers, which often operate on thin margins, recouping this hidden 0.5% could be the difference between profit and loss.

The takeaway is clear: unreliable freight isn’t a trivial inconvenience – it’s a quantifiable business risk. Lost revenue from unfilled orders, extra logistics costs, and customer defection can far outweigh any savings from using a cut-rate carrier or neglecting supply chain improvements.

Industry Evidence: What the Numbers and Case Studies Show

To put these abstract costs into perspective, let’s look at some third-party studies and real examples quantifying the toll of freight issues:

Customer tolerance for delays is low. In one survey, 23% of consumers said they won’t buy from the same store again after a delayed delivery, 21% lose trust in the brand, and 17% will actively discourage others from This illustrates how shipping issues directly translate into customer attrition, a trend likely mirrored among business buyers in the auto parts sector.

- Revenue Loss from Delays: A 2023 supply chain survey by Anvyl found 31% of SMBs lost 7–15% of revenue in 2022 due to shipping delays, and another 29% lost more than 15%. That means nearly 60% of businesses saw significant sales slip away because products didn’t reach customers on time. In the automotive aftermarket, where a single delayed part can idle an entire repair job, it’s easy to see how those losses accrue. For example, if a popular brake kit is stuck in transit, retailers will miss sales that week (and possibly lose future business if customers go elsewhere).

- Costs of Late and Damaged Shipments: A freight industry study revealed that in 2022 LTL shippers paid about $1,988 on average for each shipment that was late and damaged. This figure includes the cost of reshipping, handling returns, and other incidentals. It underscores how each logistics failure carries a hefty price tag. Multiply $1,988 by dozens of delayed shipments a year, and the financial hit climbs quickly into six figures. Another metric from the same study showed annual OTIF penalty costs averaging $253,000 per shipper (with about $83,000 of that stemming from LTL shipments. These are concrete dollars lost purely due to service failures – essentially fines for not meeting delivery promises.

- Damage Rates in Automotive Logistics: Automotive supply chains generally have high quality standards, yet transit damage remains a significant issue. Even a decade ago, industry reports noted that transportation damage caused up to half of all parts claims in inbound and aftermarket supply. While packaging and handling have improved, today’s parts (from delicate sensors to large body panels) are still vulnerable to mishandling. Every damaged part means not only a direct replacement cost, but also potential downtime – e.g. a fleet vehicle out of service longer or a customer’s repair delayed until a new part ships. As mentioned earlier, American businesses lose about 0.5% of gross sales to in-transit damage on average. For auto parts suppliers, which often operate on thin margins, recouping this hidden 0.5% could be the difference between profit and loss.

- Fleet and Service Impacts: The ripple effects of parts unavailability show up starkly in the automotive service world. In recent years, parts shortages have caused spikes in vehicle downtime for fleets, increasing maintenance costs and sidelining revenue-generating assets. An Automotive Fleet analysis noted that two years of scant replacement part supplies heightened fleet downtime and maintenance expenses, underscoring how unreliable supply lines hit end-users hard. A delayed shipment of replacement parts for a fleet means trucks or cars sit idle, appointments are missed, and companies incur opportunity costs (or even rental costs for substitute vehicles).

- Case-in-Point – Improved Freight Strategy: On the positive side, case studies illustrate how optimizing freight reliability saves money. For example, one importer consolidated their fragmented shipping network under a single logistics partner, Dedola Global Logistics, and saw immediate improvements: fewer delays, lower freight costs, and better supply visibility. By unifying air and ocean freight with one forwarder, they eliminated miscommunications and handoff errors that previously led to holdups. Such success stories show that investing in proactive logistics management pays off in tangible results.

Even modest improvements in shipping practices can yield big savings. In this example, using a slightly more protective box (bottom row) halved the in-transit damage rate from 1% to 0.5%, reducing the number of returned items from 100 to 50. Despite the new box costing 75% more, the total cost (packaging + returns) dropped from £60,000 to £42,500 – a 29% cost reduction overall. This illustrates how spending a bit more on prevention (better packaging, handling, etc.) can significantly lower downstream costs associated with damage and delays.

- The Cost of Inaction: A telling figure comes from a major ocean carrier: if a shipment is delayed enough to miss a seasonal window or a production schedule, its value can drop dramatically (25% less value after one week late, as Maersk observed). That could translate to heavy discounting of late-arriving inventory or even scrapping certain parts that are no longer needed. Additionally, the cost of uncertainty is hard to quantify but very real – managers spend countless hours expediting, checking on shipments, placating customers, and firefighting issues caused by unreliable freight. All that time could be refocused on growth initiatives if the supply chain just worked reliably.

In sum, both data and real-world experiences confirm that unreliable freight is a profit killer. Whether it’s direct losses (lost sales, rush fees) or indirect ones (customer attrition, extra inventory), the “soft” approach of tolerating delays and issues carries very hard costs. Conversely, companies that shore up their logistics see measurable improvements – faster cycle times, fewer claims, and more satisfied customers.

Current Supply Chain Challenges in the Aftermarket Auto Parts Sector

Why is freight reliability such a hot topic now? Because the post-2020 supply chain landscape has been fraught with disruptions. Aftermarket auto parts companies today face a convergence of challenges that make consistent logistics both more difficult and more critical:

- Port Congestion and Disruptions: The past few years saw unprecedented congestion at major ports, especially on the U.S. West Coast. In late 2021, ships queued up by the dozens outside Los Angeles/Long Beach – the backlog peaked at over 100 vessels waiting in early 2022, up from an average of 30 pre-pandemic. Each delay at the port ripples through the supply chain. Even in 2023, labor disputes threatened to compound congestion. For instance, an East Coast/Gulf port strike in Oct 2023, though short-lived, left 54 ships backlogged; analysts estimated each day of port closure would take about 7 days to clear in delays. In practical terms, a 3-day port shutdown can create 3+ weeks of supply chain delays. Auto parts importers felt these shocks as critical inventory sat offshore. While port flow has improved since the height of the pandemic, sporadic bottlenecks and infrastructure strains continue to pose a risk. Congestion means longer transit times, missed delivery windows, and higher costs (as carriers charge fees for waiting or rerouting).

- Global Trade Tensions: Geopolitical factors are injecting uncertainty into parts supply chains. Tariff wars and trade policy shifts can dramatically raise costs or restrict supply overnight. For example, recent U.S. trade policy discussions floated tariffs up to 25% on imports from major auto-part source countries (China, Mexico, Canada). The collision repair segment illustrates the stakes: 44% of OEM collision parts used in the U.S. are imported and virtually all aftermarket replacement parts come from abroad (e.g. Taiwan), meaning broad tariffs could add about $100 extra cost per average repair job. That’s a huge increase that would reverberate through insurance and service markets. Even aside from tariffs, political conflicts can disrupt key trade routes – early 2024 saw automakers like Volvo and Tesla suspend production due to conflicts near the Red Sea, a reminder that global turmoil can halt the flow of parts unexpectedly. For aftermarket suppliers, this means higher sourcing volatility and the need for contingency plans (alternative suppliers, routes, or stockpiles).

- Labor Shortages (Warehousing & Transportation): The logistics industry is grappling with a workforce crunch. The truck driver shortage in the U.S. remains acute – an estimated 78,000+ driver positions are unfilled as of 2024), and the shortfall could exceed 160,000 by 2030 if trends continue. Fewer drivers mean tighter trucking capacity, higher freight rates, and potential delivery delays, especially for time-sensitive part shipments that rely on long-haul trucking. Similarly, warehouse labor shortages and high turnover make it harder to process and dispatch orders quickly. Labor actions (strikes at ports, warehouses, or among delivery drivers) also loom as risks – any such disruption can stall the movement of goods. The net effect of labor gaps is that even if your parts arrive at the port on time, you might struggle to get them through the next steps efficiently. Indeed, the driver shortfall has already led to delivery delays and “bottlenecks throughout the supply chain,” with companies paying premiums for limited transport capacity.

- Supply Chain Hangovers from COVID-19: The pandemic’s impact is still being felt. Inventory imbalances (shortages of some parts, overstock of others) persist due to the whiplash in demand. For instance, semiconductor chip shortages over the past few years reduced new car production, which in turn kept older vehicles on the road longer – boosting demand for replacement parts that suppliers sometimes struggled to deliver. As one operations director noted, the scarcity of certain components has forced manufacturers to raise prices and lengthen lead times, with the cost of new vehicles hitting record highs (average $48,759 in 2024). This feeds into aftermarket dynamics: expensive new cars and long waits push consumers to maintain used cars, raising demand for aftermarket parts – but only if those parts can be sourced in time. Pandemic-related factory shutdowns, logistics slowdowns, and shifting consumption patterns have all made demand more unpredictable. Aftermarket distributors now must navigate more volatile ordering patterns and ensure they can flex with sudden spikes or drops in parts needs.

- Complexity of Aftermarket Networks: The aftermarket isn’t a single supply chain but a web of many. Parts flow from OEMs, aftermarket manufacturers, and refurbishers to distributors, retailers, repair shops, and end consumers. This multi-echelon distribution means there are more points where things can go wrong. More handoffs, more SKUs, and more regional distribution centers all increase the chances of a delay or mis-shipment. Port congestion in one region or a warehouse delay in another can upset the delicate balance of inventory across the network. Additionally, seasonality and demand surges (for example, increased collision parts demand after winter storms, or AC parts in summer) require a responsive logistics setup. The ongoing trend toward e-commerce in auto parts adds further pressure for fast, reliable delivery direct to consumers.

In short, aftermarket auto parts logistics in 2025 sits at the nexus of global and domestic challenges. Infrastructure and labor constraints, macroeconomic shifts, and geopolitical events are making it harder to ensure the right part gets to the right place at the right time. This context is exactly why shippers and importers are seeking stable partnerships and smarter strategies – the old “ship and pray” approach is no longer tenable amidst such headwinds.

Mitigating Freight Risks: Strategies and Benefits

Given these challenges and the high cost of unreliability, companies are focusing on supply chain resilience and freight optimization. The goal is to turn logistics into a competitive advantage rather than a constant headache. Here are some strategies being employed, and the benefits they offer:

- Diversified Shipping and Routing: To avoid single points of failure, savvy importers are diversifying their carriers and routes. This might mean splitting shipments between West Coast and East Coast ports, or using a mix of ocean and air for critical items. By multisourcing freight capacity and having alternate lanes ready, companies can reroute around congested hubs or geopolitical trouble spots. The benefit is improved reliability and agility – if one pipeline shuts, another can carry the load, reducing the chance of total stockouts. Of course, managing this complexity requires visibility and coordination (often with a 3PL’s help), but it pays off by preventing catastrophic delays.

- Improved Customs Compliance & Clearance: Customs delays are a notorious wildcard for importers. DGL (Dedola Global Logistics) and similar logistics experts emphasize meticulous customs documentation and proactive compliance to speed up clearance. This includes pre-verifying tariff codes, having all paperwork in order, and leveraging local customs broker expertise. By doing so, importers can slash clearance times and avoid costly holds. For example, one DGL client testimonial noted that switching to DGL’s customs brokerage cut their average clearance from 10 days to 4 days – a 60% time reduction. Faster clearance not only gets product on shelves sooner but also avoids demurrage fees (which can run $100–$300 per container per day in port fees if your container sits awaiting customs). The benefit here is twofold: lower direct fees and faster time-to-market for the goods.

- Robust Packaging and Handling Protocols: As the earlier damage example illustrated, investing in better packaging and handling procedures reduces breakage. Auto parts, especially heavy or oddly shaped ones, need proper crating, padding, and sometimes climate control. Leading shippers work with packaging engineers or use services like consolidation and transloading to minimize handling damage. The payback is a lower damage rate (fewer claims) and thus less wasted cost on returns and scrapped goods. In an industry where 0.5% of sales is at risk from transit damage, halving your damage rate could recoup that margin. Additionally, customers notice – fewer damaged deliveries = happier customers, which bolsters your brand reputation.

- End-to-End Visibility Systems: Technology is a big ally in reliability. Platforms that offer real-time tracking of shipments, predictive ETA updates, and proactive alerting of issues enable companies to respond fast and keep customers informed. For instance, DGL provides a tracking platform (“TrakItPro”) that gives clients a single pane of glass for all shipments – air, ocean, and land. With end-to-end visibility, if a delay does occur (say, a vessel arrival slips by a day), the importer can immediately adjust downstream plans (like rescheduling deliveries or notifying customers). Visibility also helps identify bottlenecks and hold partners accountable to service levels. The overall benefit is greater control and fewer surprises, turning the supply chain into a more predictable part of the business.

- Unified Freight Management (One-Stop Logistics): A trend among importers is consolidating their freight and logistics with a single expert provider rather than juggling multiple forwarders, brokers, and carriers. The earlier DGL case study highlighted how a unified freight solution eliminated “handoff” delays and errors. One point of contact managed the whole journey, leading to clearer communication and accountability. The client saw faster response times and more synchronized operations. In general, partnering closely with a capable 3PL or freight forwarder can yield tailored solutions (like optimized consolidation of shipments, or mode shifting for speed vs. cost) that an ad-hoc approach might miss. The benefit is a streamlined supply chain that works in concert rather than a fragmented one where left hand and right hand might not coordinate, resulting in delays.

- Scenario Planning and Buffer Strategies: Thought leaders in supply chain now engage in more rigorous risk planning. This could involve maintaining strategic safety stock of fast-moving parts, or at least identifying alternates and emergency suppliers for critical components. Some are implementing “control tower” teams that simulate scenarios (e.g., “What if port X closes for a week?”) and have playbooks ready. While holding extra inventory has a cost, for crucial parts the cost of not having them can be higher (e.g., if a $5 part prevents the sale of a $500 repair job). The key is to strike a balance – use data to identify where a buffer is truly cost-justified. The benefit is resilience: when (not if) a disruption strikes, these companies can cushion the blow and maintain service to customers, avoiding those catastrophic failure costs outlined earlier.

In conclusion, unreliable freight in the aftermarket auto parts sector carries very real costs – from immediate financial hits to long-term customer fallout. However, by understanding these impacts and addressing today’s supply chain challenges head-on, companies can turn logistics into a strength. Data and industry examples make it clear that investing in reliable freight solutions (whether through strategic 3PL partnerships, better processes, or technology) yields dividends in higher revenue, lower costs, and happier customers. In a time of ongoing uncertainty – be it a port strike, a driver shortage, or a tariff threat – having a robust, agile logistics strategy isn’t just operational overhead, it’s essential for business resilience and growth. As a logistics provider at the forefront, Dedola Global Logistics aims to illuminate these issues and help aftermarket companies navigate toward more reliable, cost-effective supply chains. With the right approach, the risks of freight disruption can be mitigated, and the benefits – in efficiency, savings, and customer loyalty – are yours to seize.